Product Details

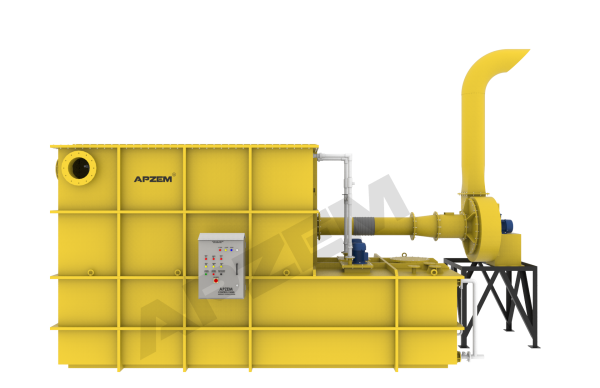

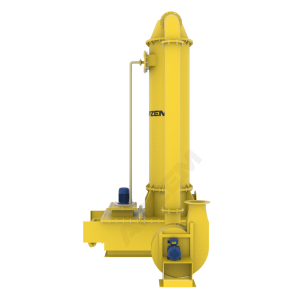

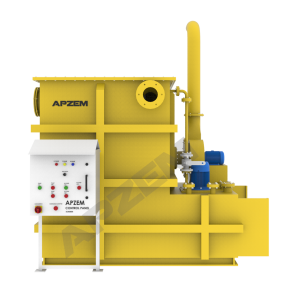

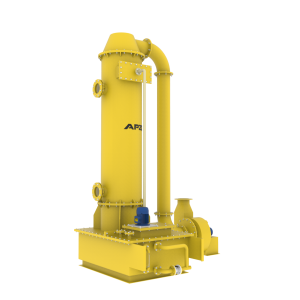

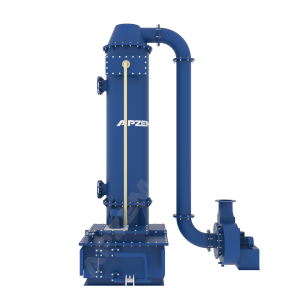

Hard Chrome Scrubber

Hard Chrome scrubber

Apzem design and develop a scrubber to capture chromic acid emits from chrome plating and reclaim 99 % of captured chromium back to plating process. This is main advantages of scrubber, the cost of incorporating scrubber can be taken back with in a years.

Product CatalogueDescription

Hard Chrome Scrubber

Hard Chrome scrubber

Apzem design and develop a scrubber to capture chromic acid emits from chrome plating and reclaim 99 % of captured chromium back to plating process. This is main advantages of scrubber, the cost of incorporating scrubber can be taken back with in a years.

Chrome Plating

It is an electroplating of thin layer chromium on an object. Plating bath containing chromium solution is charged by applying electrical charge to cause the chromium metal to detach from solution and adhere on objects placed in the solution. Most widely used chromium is Hexavalent Chromium [Cr(VI] for decoration of objects and used as anticorrosive agents. The hexavalent chromium will be emitted from plating bath as mist or aerosol when applying electrical charge. Also, the hexavalent chromium mist can be generated from chromic acid anodizing processes. Exposure to the Hexavalent chromium causes adverse impact to health and surrounding areas.

Chemical emissions from the tank

There are many factors to affect the emissions from bath. These are follows:

- Chemical concentration

- Vapor pressure of solution

- Electrification

- Temperature of solution in tank

- Process types

- Agitation

Exposure to Chromic acid

- Hexavalent chromium [Cr(VI)] targets respiratory system, skin, eyes and it is well known to cause cancer.

- Large number of workers are exposed to chromium. The industries where the workers are exposed potentially with high concentrations are metallurgy, tanning, automobile industries.

Exposure limit

- Permissible exposure limit (PEL) of 5 µg/m3 measured as Cr(VI) for 8-hour TWA. However the action level is set at 2.5 µg/m3 for 8- hour TWA.

- Apzem design capturing technique using feasible engineering to control and reduce the emission level at below the PEL.

- Proper Engineering techniques are used to achieve the maximum removal efficiently. It is required to design hood (Local Exhaust Ventilation, LEV) around the plating bath to capture the vapor. The hood is designed with required slot area to achieve capture velocity as per ACGIH standard. The hood is connected to scrubber system to move the captured air to the scrubber.

- We design scrubber using composite mesh pads. The mesh pads are incorporated at several stages to get high efficiency progressively. The scrubber system has composite mesh pads, spray header systems and tank to recover the acids. The composite mesh pad (CMP) consist of three stages of interlocking fiber layers, which are densely packed and placed between two reinforced grids. The fiber layers are arranged in such a way that smallest diameter layer placed in the center of pad and larger diameter fiber layers are placed on both sides.

- The air with chromic acid moisture is passed through the composite mesh pad, where the mist impinges on the mesh. The mist collide and attach on the first stage larger diameter fiber layer. The captured mists combine and forms larger droplet, and pass through small diameter layers at center of mesh. The larger droplets either drain to bottom or re-entrain in the gas stream and pass to second larger diameter layer, where the larger droplets are captured. The first stage does coarse separation of droplets with bulk removal. The residual mists are further collected in intermediate stage where it acts as polishing section to increase the efficiency further. Hence, collectively the efficiency is 99 % of mist up to 1 micron size. This degree of efficiency is required to achieve the stringent emission limits.

- The captured chromium mist on the mesh pads are washed by applying water spray on the mesh pad and the diluted chromium can be recovered in the bottom tank. Sequential timer helps to spray water intermittently to clean/wash the mesh pad to decrease the pressure drop and increase the capturing efficiency

- Recovery of chromium

- Removable composite mesh pads which allow for easy cleaning and maintenance

- Corrosion resistance mesh pad

- Removable spray headers for easy maintenance

- Hexavalent chromium plating

- Trivalent chromium plating

- Electroplating (Nickel, Chromium)

- Anodizing

- Electro polishing

- Etching

- Pre cleaning

- Brightening

Features of

Features of Hard Chrome scrubber

- Air handling volume : up to 20000 CFM

- Pressure drop : 200 mm W.C.

- Removal Efficiency : Above 99 %

- Material of Construction : PVC / PP / FRP

- Mesh Pad : 3 Layers of composite mesh pad

- Spray Nozzle : ½ inch size

- Water recirculation pump : PP vertical seal less pump

- Structure : Rigid sub base

- Safety Accessories : Drain valve with ball valve, Water inlet valve, Overflow provision

- Water level indicator, Inspection glass port

- Scrubbing liquid : Water

- Blower : High efficiency blower, Motor make: ABB/BBL/CGL

- Control panel : Control panel for Blower and pump with timer control

- Pump make: SRB/ Anala, Motor make: ABB/ CGL/ BBL

- Storage tank capacity : Up to 3000 Litres

https://www.apzem.in/index.php/product/hard-chrome-scrubber/