Product Details

Portable Welding Fume Extractor

Welding fume or smoke contains harmful elements such as Manganese, Chromium, Nickel, Zinc etc. Continuous Inhaling of welding fumes may cause Weld Fume Fever, Headaches and dizziness, Irritated eyes, nose and throat, Chest pain, Respiratory damage, Difficulty breathing, Lead poisoning, Nervous system damage etc.

Apzem’s Welding Fume Extraction System and portable welding fume extractor are specially designed such that it suits for all types of welding applications such MIG Welding , TIG Welding , Stick Welding , Cleanroom Welding , Stainless Steel Welding as require static as well as movable extraction unit.

Description

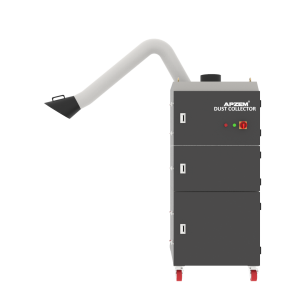

Trolley Type Fume extractor

Apzem offers a portable welding fume extractor in such a way that they can be easily moved. Portable welding fume extractor filter is used to capture hazardous fumes generated while welding. Welding fume extractor system comes with heavy-duty industry grade metal body and Self Suppotive 360 Degree Rotatable Flexible Arms with hoods.

Portable Welding Fume Extractor – Working :

APZEM offers Trolley type Welding Fume Extraction System is designed to efficiently control the hazardous fumes that are generated during the welding, Soldering or laser cutting/marking operations. The welding fume absorber is designed in such a way that no fumes can escape into the atmosphere. The Welding Fume Extraction System arm is a 360-degree rotatable arm with an adjustable hood that can collect the fumes initially in the source itself. The anti-spark protection system prevents the hot air particles from directly entering into the extractor. The filters are cleaned periodically using automatic reverse pulse system, thus increasing the life and maintaining the efficiency of the filters.

- Three way spark arrester

- Fully automatic PLC based filter cleaning system

- Powerful extraction with integrated fan

- Large filter surface area and longer life span

- Full front access for operation and maintenance

- Easy filter replacement

- Easy dust tray cleaning

- 12 gauge, powder coated, sturdy construction

- Fully functional built in castor

| Model No. | PD 1030 |

| Air Handling Volume | 1,500 m3/hr. 850CFM |

| Vacuum (Max) | 150mm WC (6” WG) |

| Suction Port | 2 Nos |

| Power Requirements | 3 HP 3 phase, 2.2 Kw Max, 50/60Hz, 430V AC |

| Sound Rating | 78 dBA |

| Operating Temperature | 05 – 85 Deg C |

| Stages of Filtration | Cartridge Filter Collecting Tray |

| Filter Type | Cartridge type |

| Filter Cleaning | Automatic Sequential Reverse air Pulse Jet Cleaning |

| Inlet Size | 150mm * 2 Nos |

| Construction | Heavy Gauge, Robust construction, fully welded cabinets |

| MOC | Cabinet fully made of Mild Steel. |

| Finish | Smooth Surface Finish |

| Exterior Finish | Duly coated with powder coating |

| Warranty | 1Year |

- Flame proof motor and control panel

- Flame proof solenoid valves

- Antistatic filter

- Single inlet options available