Product Details

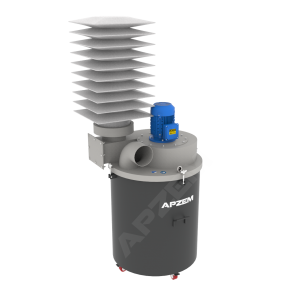

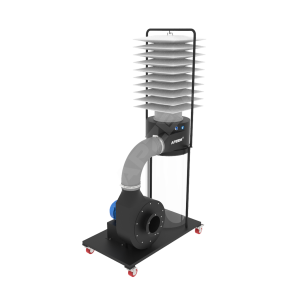

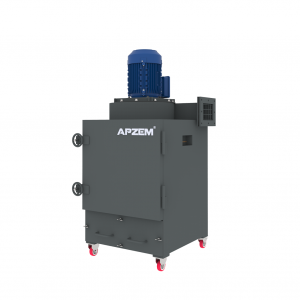

Pulsejet Cartridge Dust Collector

APZEM Cartridge Dust Collectors have a large filter area in proportion to their size and are suitable for dry, fine dust and can be equipped with lots of different types of filter materials. The Apzem cartridge collector is the optimum solution to a variety of in-plant air quality problems. The compact modules help conserve valuable space, and can be interconnected to accommodate the largest air cleaning task. Apzem collectors may be tailored to specific application requirements with a wide selection of cartridge types, options, and accessories.

Product Catalogue Send EnquiryDescription

PULSE JET CARTRIDGE DUST COLLECTOR

PULSE JET CARTRIDGE DUST COLLECTOR

Dust Collectors have a large filter area in proportion to their size and are suitable for dry, fine dust and can be equipped with lots of different types of filter materials. The Apzem cartridge collector is the optimum solution to a variety of in-plant air quality problems. The compact modules help conserve valuable space, and can be interconnected to accommodate the largest air cleaning task. Apzem collectors may be tailored to specific application requirements with a wide selection of cartridge types, options, and accessories.

- Dust bags are 99% efficient.

- High filtration area.

- Easy handling of dust drum for dust disposal.

- 12 gauge, powder-coated, steel casing.

- Automatic pulse cleaning increases filter life

OPTIONAL FEATURES:

- DUST DRUM SENSOR.

- MANUAL/PNEUMATIC DAMPER FOR DUST DRUM

- FLAME PROOF MOTORS & CONTROL PANELS

- FILTER CHOKE SENSOR

- FILTER BURST SENSOR

- ANTISTATIC FILTERS

- FIRE SENSOR

- SPRINKLER DESIGN FOR FLAMMABLE DUSTS

- CYCLONE PRE-FILTRATION SYSTEM

- Steel making

- Iron foundries

- Cement and rock products

- Wood industries

- Glass making

- Industrial boilers

- Coal handling

- Metal and plastics recycling

- Food and pharmaceutical

- General industrial dust collection

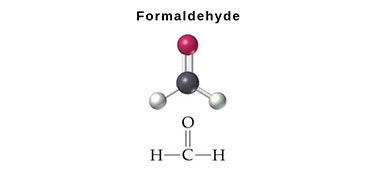

- Chemical Processing

| MODEL NO. | AIR FLOW RANGE (CFM) | FILTER AREA | FILTER ARRANGEMENT | NO OF VALVES | FLOOR OCCUPATION DIMENSIONS (WITHOUT LADDER SETUP) (L X WX H) IN MM |

||||

| (in SQ.M) | (in SQ FT) | R x C | L | MAIN CASE HEIGHT |

W | H | |||

| AHPB30 | 1250-2500 | 28 | 302.98 | 2 x 2 | 4 | 1240 | 1725 | 1700 | 3295 |

| AHPB40 | 1700-3400 | 40 | 432.83 | 2 x 2 | 4 | 1105 | 1725 | 2000 | 3295 |

| AHPB60 | 2500-5200 | 60 | 649.24 | 2 x 3 | 6 | 1580 | 1725 | 2000 | 3295 |

| AHPB80 | 3500-7000 | 80 | 865.66 | 2 x 4 | 8 | 2055 | 1725 | 2000 | 3295 |

| AHPB120 | 5200-10400 | 120 | 1298.48 | 2 x 6 | 12 | 3005 | 1725 | 2000 | 3295 |

| AHPB40-1 | 1800-3650 | 42 | 454.47 | 3 x 2 | 6 | 1105 | 2150 | 1700 | 3720 |

| AHPB60-1 | 2600-5200 | 60 | 649.24 | 3 x 2 | 6 | 1105 | 2150 | 2000 | 3720 |

| AHPB90-1 | 3900-7800 | 90 | 973.86 | 3 x 3 | 9 | 2060 | 2150 | 2000 | 3720 |

| AHPB120-1 | 5200-10400 | 120 | 1298.48 | 3 x 4 | 12 | 2585 | 2150 | 2000 | 3720 |

| AHPB180 | 7800-15600 | 180 | 1947.72 | 3 x 6 | 18 | 3635 | 2150 | 2000 | 3720 |

| AHPB80-1 | 3470-6900 | 80 | 865.66 | 4 x 2 | 8 | 1535 | 2575 | 2000 | 4145 |

| AHPB160 | 6900-13850 | 160 | 1731.31 | 4 x 4 | 16 | 2585 | 2575 | 2000 | 4145 |

| AHPB240 | 10400-20800 | 240 | 2596.96 | 4 x 6 | 24 | 3635 | 2575 | 2000 | 4145 |

| AHPB320 | 13850-27700 | 320 | 3462.61 | 4 x 8 | 32 | 4685 | 2575 | 2000 | 4145 |

| AHPB400 | 17300-34600 | 400 | 4328.26 | 4 x 10 | 40 | 5735 | 2575 | 2000 | 4145 |