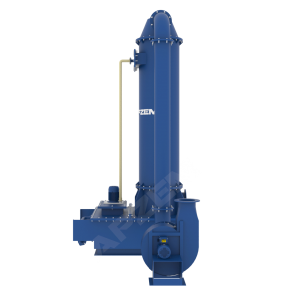

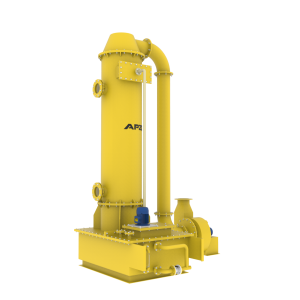

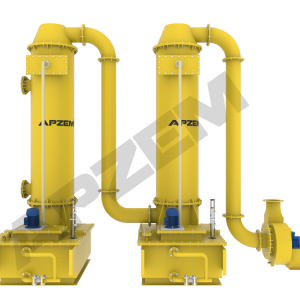

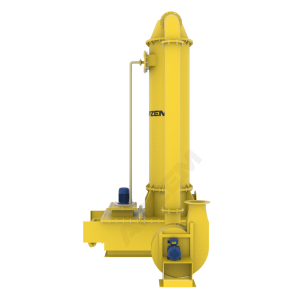

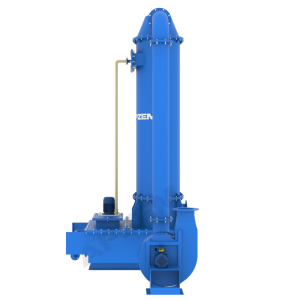

Wet Packed bed scrubber

Apzem Packed bed Scrubber are custom designed to capture sub micron particulate matter, chemical fumes, odors, and other water / chemically soluble fumes and Vapors generated in industrial process. All wet scrubber works on the principle of absorption technology, where the pollutants is made in contact with scrubbing liquid. The pollutants gets absorbed by scrubbing liquid either physical or by chemical means. The capturing efficiency of the scrubber can be increased by increasing the time of contact of flue gas with scrubbing liquid.

In packed bed scrubber we use rings, saddles etc so called packings to increase scrubbing efficiency. We supply counter flow (vertical scrubber ) and cross flow type (Horizontal scrubber) and multi scrubber arrangements based on site constraints and efficiency required. The sizing of scrubber, selection of scrubber solution, Material and inner lining is critical in designing wet scrubber for a particular application.

Products

H2SO4(Sulfuric Acid) Scrubber

H2SO4(Sulfuric Acid) Scrubbersulfuric acid scrubber

Many chemical industries generates and exhausts sulphur based substances such as sulphuric acids or sulphur dioxide from various processes. Sulfuric acid fumes are very corrosive and it is strongly irritant to the respiratory if is directly inhaled. Apzem have experienced in controlling and neutralizing the sulphuric acid fume using a packed bed column with caustic recirculation.

[su_button url="#" target="blank" background="#8dc63f" size="7" radius="0" icon="icon: file-pdf-o"]Product Catalogue[/su_button]

HCL SCRUBBER

HCL SCRUBBERHcl gas is colorless, pervasive and corrosive, mostly emitted from process reactors, Hcl storage tanks while filling and laboratory. Hcl gas emits easily from aqueous solution of concentrated hcl at atmospheric temperature and diluted hcl at higher temperature. The high vapour pressure of hcl tends to emit the fumes.

[su_button url="#" target="blank" background="#8dc63f" size="7" radius="0" icon="icon: file-pdf-o"]Product Catalogue[/su_button]NaOH Scrubber

NaOH ScrubberCaustic scrubbing technology is used for removal of acidic pollutants in exhaust gas from different industries.A cylindrical column consist of packing materials and spray nozzles in which the contaminated gas is passed. Pollutants from the gas dissolve in the liquid based on the absorption technology. Spray nozzles are arranged in such a way that spray zones should cover cross sectional area of column. There is packing material in the tower to enhance contact between liquid and gas.

[su_button url="#" target="blank" background="#8dc63f" size="7" radius="0" icon="icon: file-pdf-o"]Product Catalogue[/su_button]NH3(AMMONIA)SCRUBBER

NH3(AMMONIA)SCRUBBERNH3 Ammonia Scrubber

Ammonia is a colorless gas made of hydrogen and nitrogen, a strong odor causing gas. It is poisonous if inhaled directly in large quantities and direct exposure causes eye, nose and throat irritation in less concentration.https://www.apzem.in

[su_button url="#" target="blank" background="#8dc63f" size="7" radius="0" icon="icon: file-pdf-o"]Product Catalogue[/su_button]NOx Scrubber

NOx ScrubberNitrogen released from fuel combustion process reacts with oxygen and forms Nitric Oxide (NO). The Nitric Oxide is a colorless gas and it will be oxidized into Nitrogen dioxide (NO2) upon reacting with oxygen. This NO2 has odorous and acidic in nature, causes hazardous to human health and the environment, even in typically low concentrations.

[su_button url="#" target="blank" background="#8dc63f" size="7" radius="0" icon="icon: file-pdf-o"]Product Catalogue[/su_button]Phosphating Scrubber

Phosphating ScrubberPhosphating is the widely used pretreatment process for metal surfaces and polishing of ferrous and non ferrous materials. It plays an important role in automobile and appliances industries because of its corrosion resistance, wear resistance and speed of operation. Phosphate coating is typically used to coat any steel parts to prevent from corrosion and can be used for pre treatment of any material or equipment before doing painting or coating. Chemicals used for phosphate coatings are Manganese, Iron and Zinc.

[su_button url="#" target="blank" background="#8dc63f" size="7" radius="0" icon="icon: file-pdf-o"]Product Catalogue[/su_button]