Product Details

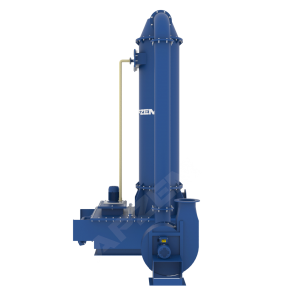

CVD Scrubber

cvd scrubber

Deposition by chemical reaction between reactants. It is a chemical process that deposits thin film of diverse chemical substances. A substrate is exposed to volatile precursors and react to generate required deposit. Simultaneously, the byproducts also generated from the process. Precursors used to deposit silicon is silane (SiH4).

Product CatalogueDescription

CVD Scrubber

cvd scrubber

Chemical Vapor Deposition

Deposition by chemical reaction between reactants. It is a chemical process that deposits thin film of diverse chemical substances. A substrate is exposed to volatile precursors and react to generate required deposit. Simultaneously, the byproducts also generated from the process. Precursors used to deposit silicon is silane (SiH4).

It is very flexible process mostly used in production of powders, coating and monolithic parts. Using CVD, we can produce any metallic or non-metallic elements. It is mainly applied in semiconductor industries, as part of device fabrication process in semiconductor to deposit various films including silicon, siO2, silicon nitride, titanium nitride, silicon germanium. It is a linear growth process in which, gas deposits a thin film on wafer. It produce very thin silicon dioxide because of thin film deposition rather than thick grown film. Because of its thin film with high electrical resistance, it is mainly used in semiconductor devices, ICs and some other applications. CVD is performed when external layer is required but silicon will not be oxidized.

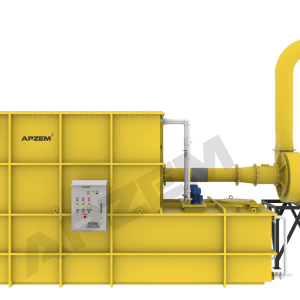

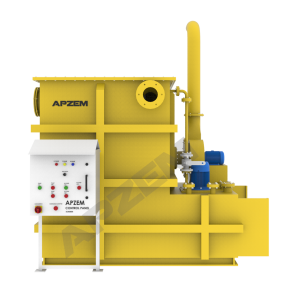

Apzem approach is to eliminate fumes from CVD process using adsorption technology. Specialized adsorption media will be used to get higher removal capacity rather than normal media. The saturated media can be disposed easily in non-hazardous landfills.

- Performance Guaranteed

- Low maintenance

- Low pressure drop, Minimal energy cost

- No water, ETP is not required

- No hazardous by-product

- Chemical Reactor vents

- Laboratory

- Hospital

- Food processing area

- Storage tank vent

- Air flow rate from 50 CFM to 2000 CFM

- Concentration: 1 ppm to 200 ppm (continuous) up to 2000 ppm (Intermittent)

- Removal efficiency: up to 99.99 %

- Material of Construction: MS with Epoxy lining

- Construction: Heavy Gauge, Fully welded cabinet, robust construction

Dimensions

| Model | Air flow rate (CFM) | Dimension

Diameter (mm) |

Height (mm) |

| ADS-30 | 100 | 300 | 1400 |

| ADS-45 | 300 | 450 | 1500 |

| ADS-60 | 500 | 600 | 1500 |

| ADS-75 | 800 | 750 | 1650 |

| ADS-90 | 1000 | 900 | 1700 |

| ADS-105 | 1500 | 1050 | 2000 |

| ADS-120 | 2000 | 1200 | 2200 |

https://www.apzem.in/index.php/product/cvd-scrubber/

Blower: Direct drive, High efficiency, Low noise