Product Details

Hybrid Scrubber

voc scrubber

Apzem Hybrid scrubber reduces SOx emissions to meet the environmental regulations at coastal region. The main source of SOx emissions is burning of fossil fuel which contains high sulphur component in diesel engine. The high sulphur content fuel is used for marine applications because of its less Hybrid expensive. Switching to low price fuel to high price fuel causes burden to ship owners. This causes the SOx emissions in marine environment, thus disturbs marine eco systems, harms human health and violate the regulations. In order to control the SOx emissions from ship engines, Apzem designed and developed a hybrid wet scrubber.

Product CatalogueDescription

Hybrid Scrubber

voc scrubber

Hybrid scrubber reduces SOx emissions to meet the environmental regulations at coastal region. The main source of SOx emissions is burning of fossil fuel which contains high sulphur component in diesel engine. The high sulphur content fuel is used for marine applications because of its less Hybrid expensive. Switching to low price fuel to high price fuel causes burden to ship owners. This causes the SOx emissions in marine environment, thus disturbs marine eco systems, harms human health and violate the regulations. In order to control the SOx emissions from ship engines, Apzem designed and developed a hybrid wet scrubber.

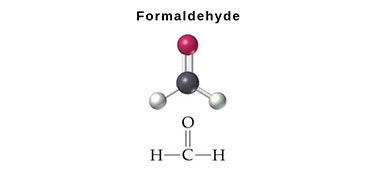

Working Principle of Wet Scrubber

It works based on the absorption with chemical reaction, involved to remove pollutants from exhaust gas by dissolving into the liquid. A central piece of equipment, called packed bed column, in which the polluted gas is fed from the bottom and pass upward through packing material. At the same time, solvent is sprayed from the top to wash the pollutants. The down come liquid is again recirculated back using pump. SOx scrubber includes packed bed column, scrubber tank, re-circulation pipe connected with solvent spray nozzle. Recirculation pump, Instrumentations, Suction blower and Control panel. All the parts involved in the scrubber unit is designed and selected based on the standard design criteria. Packed column helps to achieve heat transfer and mass transfer. The exhaust gas contains SOx mostly has high temperature than atm. The packed column is utilized in cooling of hot gases and dissolving acid gases into the solvent. Water will be used as solvent for the physical absorption. However, Alkali solution will be used for continuous effective scrubbing. Packing material with high surface area is used to increase intimate contact between gas and liquid.

Generally, there are 3 type of Scrubber for this applications.

- Open loop scrubber

- Closed loop scrubber

- Hybrid Scrubber

Open loop Scrubber

There is no re-circulation of used water. The water is used as single pass through the column. Once the water is passed through column by single pass, it is discharged directly into the sea. The seawater will be used as fresh liquid for each time to scrub the pollutants. This type of scrubber is mostly used currently.

Closed loop Scrubber

The scrubbing liquid (sea water) used in this process is re-circulated continuously until it reaches discharge point based on conductivity.

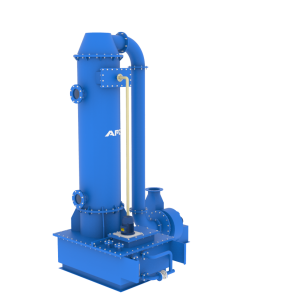

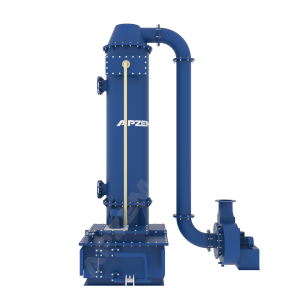

Hybrid Scrubber

The hybrid scrubber can be run in both open loop and closed loop mode. The scrubbing liquid can be directly discharged into the sea or recirculated back based on use. This scrubber can be installed on all vessels type, tanker, cruise ships, cargo carriers etc. It is important to select the material of construction. The material used for fabricating scrubber will be exposed to sulphur from the exhaust gases and also seawater causes wet corrosion. These parameters will cause corrosion to the materials used for scrubber system. So, life span of the scrubber system depends on material used and its corrosion resistance.

| AIR HANDLING VOLUME |

|

| TYPE |

|

| SYSTEM PRESSURE DROP |

|

| REMOVAL EFFICIENCY |

|

| MOC |

|

| PACKING MATERIAL |

|

| FLOODING |

|

| NOZZLES |

|

| STRUCTURE |

|

| CONTROL SYSTEM |

|

| ACCESSORIES |

|

| SAFETY ACCESSORIES

|

|

| Scrubbing liquid |

|

| Blower |

|

| Control panel |

|

https://www.apzem.in/index.php/product-category/scrubber/voc-scrubber/