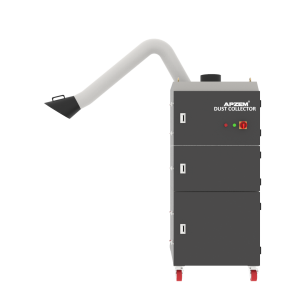

Product Details

DOWNDRAFT TABLE

Apzem downdraft and backdraft workbench dust fume collectors are designed as a safe and ergonomic workstation for capturing fumes and dust particles during grinding, Plasma cutting, welding, and other mild power handling applications protecting workers from inhaling it.

Send EnquiryDescription

DOWNDRAFT TABLE

Downdraft Table – Working

Apzem downdraft and backdraft workbench is used to capture dust and fume particles during grinding, Plasma cutting, welding and other medium to heavy duty applications. Downdraft table can be used to capture the welding fumes effectively with the help of downdraft and backdraft fume extraction. Downdraft grinding table removes fumes and dust generated during the grinding process through the working surface and backdraft panel. Downdraft fume extractor is suitable for many applications like grinding, welding and plasma cutting process. Downdraft welding table has three way spark arrester system, captures the sparks before it get into the filter chamber.

FEATURES

- Strong Backdraft (80%) and Downdraft (20%) Extraction Capacity – Ideal for welding, grinding(1), and light duty plasma cutting.

- Industry Leading Three Stage Spark Arrestor System – Captures hot particulate before it can get into the filter chamber.

- All Controls and Doors on Front – Offers complete access to filters and collection draws for easy maintenance.

- Pull out drawers for easy cleaning.

- Three way spark arrester

- Low noise level operations

- Fully automatic PLC based filter cleaning system.

- Powerful extraction with integrated fan.

- Easy to operate.

- Large filter surface and long filter lifespan.

- Sturdy construction

- Reliable, low maintenance operation.

- Welding

- Grinding

- Power handling

- Plasma cutting

- Mild coating and spraying

- Fettling

| BASIC DETAILS | DT1500 |

| SUCTION CAPACITY (CMH/CFM) | 2550/1500 |

| OVERALL DIMENSIONS (L X W X H) | 1390 X 1000 X 1610 mm |

| WORKBENCH HEIGHT | 900mm |

| MACHINE WEIGHT (APPROX.) | 350kg |

| WOOD PACKING SIZE (L X W X H) | 1600 X 1210 X 1860 mm |

| SHIPPING WEIGHT (APPROX.) | 500kg |

| MOTOR POWER | 2HP |

| MOTOR SPEED | 1440 RPM |

| POWER SUPPLY | 3 PHASE / 50Hz |

| RATED CURRENT | 4.49 A |

| NOISE LEVEL | 80dB |

| STATIC PRESSURE | 100mm OF WG |

| IMPELLER SIZE | 490mm DIA |

| FILTERS | |

| PRE-FILTER (BOX TYPE) | 90% EFFICIENCY @ 10MICROMETER |

| NON WOVEN SYNTHETIC FILTRATION MEDIA | |

| CARTRIDGE FILTER (DIN TYPE) | 9 sq.m |

| SPUN BONDED POLYESTER 260GSM | |

| FILTER EFFICIENCY | 98% @ 2 MICRONS |

| HEPA FILTER (OPTIONAL) | 99.97% @ 0.3 MICRONS |

| COMPRESSED AIR TANK | 9 LITRES |

| COMPRESSED AIR PRESSURE | 5-6 bar |

Confirming to IFA-W3 according to EN 15012-1